Typical performance of Micronor hermetic products:

- Hermeticity: leak rate less than 10-8 mbar.l/s

- Electronic insulation: insulation resistance greater than 10 GΩ

- Breakdown voltage: 500 to 3,000 V

- Temperature of use: from -180°C to +300°C after coating

Special designs allow for higher performance.

Please feel free to contact us.

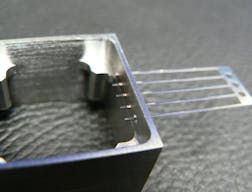

GLASS-METAL SEALING

Matched sealing: Creation of a chemical seal between glass and metal. Glass and metal must have close thermal expansion. Implemented especially with the Dilver P1 and the Iron Nickel Alloys.

Compression sealing: The mechanical strength and the hermeticity are obtained thanks to the compression exerted by the metal body on the glass. This is the technology used when the body of the part is made of stainless steel or steel.

Titanium sealing: The is a combination of the two technologies above.

Products: Unitary hermetic insulating seals, Multi-pass hermetic insulating seals, Microelectronic housings, Special high-performance models

Materials (non-exhaustive list): Dilver P1 (Kovar), Iron Nickel Alloys, Stainless Steel, Titanium, Ceramic, Steel, Inconel, Copper

CERAMIC-METAL BRAZING

Brazing consists of assembling 2 parts by melting an element that may have a different composition from the assembled parts.

Unlike soldering, brazing makes it possible to assemble parts of very different types.

- Metallisation brazing: The process of ceramic metallisation is necessary before being able to braze with a conventional alloy

- Active brazing: Integration of an active element into the brazing that reacts with ceramic to create a permanent seal. (Vanadium, Niobium, Zirconium, Titanium)

Products: Insulators, Implantable seals, Connectors

Materials: Ceramic, Dilver P1 (Kovar), Stainless steel, Titanium, Copper

METAL-METAL BRAZING

Products: Tubes, Cryogenics, realisation of mass contacts

Materials (non-exhaustive list): Dilver P1 (Kovar), Iron Nickel Alloys, Stainless Steel, Titanium, Ceramic, Steel, Inconel, Copper

SAPPHIRE-METAL BRAZING

Products: Portholes

Materials: Titanium

METALLISATION

In most applications, alumina parts should be metallised to allow brazing with a wide variety of metals.

Micronor offers 2 complementary technologies to achieve this operation:

- Moly manganese metallisation. This is the most common method. The metal powders are mixed with organic compounds to form a paint that is applied to the ceramic, for example with a brush.

- After brazing, this method allows to obtain hermetic parts and very good mechanical strength PVD metallisation uses a plasma to pull atoms out of a target and deposit them on the parts.

This technology makes it possible to achieve implantable hermetic seals.

Products: Insulators, Implantable Seals, Connectors

Materials: Ceramics and other materials

TABLETING

Micronor 7 Doloy has kept a glass bead manufacturing workshop required for Glass-Metal sealing. Thanks to the hand-made and tailor-made production of these micronor 7 glass beads, Doloy is able to respond to specific technical demands by proposing adapted technological solutions.

This specificity of Micronor 7 Doloy offers its customers:

- a reduced lead time due to on-site fabrication

- optimal control of the glass volume of the bead, particularly essential for microwave beads

- an easily adjustable glass thickness if necessary